| Availability: | |

|---|---|

INFNI-WM -200/400

Infni laser

Product Advantages:

1.Ceramic converging cavity is imported from the Britain. It is corrosion resistant and high temperature resistant ,and has 8-10 years service life.

2.High production efficiency and high welder speed, realizing automatic mass production on the production line

3.The laser head can be adjusted for 360 degree

4.The size of the light spots can be adjusted

5.The work bench can be moved in two dimensions

Application:

Suitable for welder of kettle, vacuum cup, stainless steel bowl, sensor, tungsten wire, high power diode(triode),aluminum alloy, laptop sheel, mobile phone battery, door handle, mould, electric apparatus fittings, filter, nozzle, stainless steel products, golf head, zinc alloy and so on.

artworks weld point straight line, circle, square or any plane graphs drawn by AUTOCAD.

Datas:

Model No | LS-WM200 | LS-WM300 | LS-WM400 | ||

Max. laser power | 200W | 300W | 400W | ||

Laser wave-length | 1064nm | ||||

Solder joint range | 0.1-3.0mm | ||||

Solder joint size | 0.2-3.0mm | ||||

Pulse width | ≤20ms | ||||

Pulse frequency | ≤50Hz | ||||

Mono pulse Max power | 100J/150J/200J | ||||

Type of Laser | Nd:YAG | ||||

Sighting positioning precision | RED light,CCD monitor system(optional) | ||||

Work bench stroke | 200×200mm - 1200×1200mm(optional) | ||||

Positioning accuracy | 0.02mm | ||||

RepeatablePositioning accuracy | ±0.01mm | ||||

Loading ability | ≤200KG | ||||

Power supply | 380V/3-phase/50Hz/40A | 380V/ 3-phase/50Hz/60A | 380V/ 3-phase/50Hz/60A | ||

Power system | 9KW | 12KW | 14 KW | ||

Cooling way | Water cooling | ||||

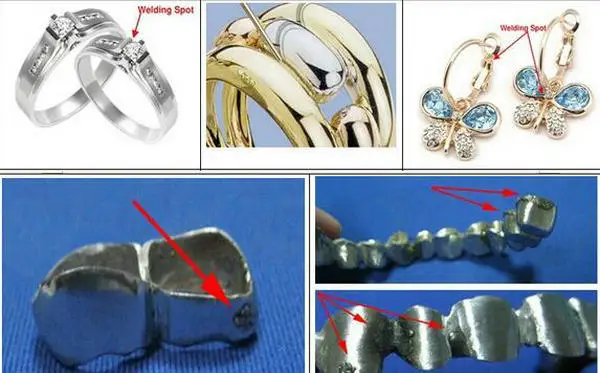

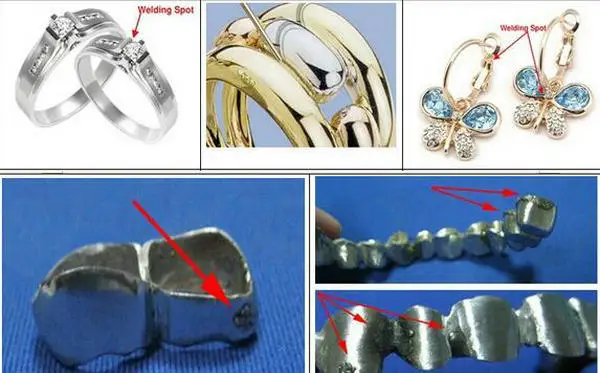

Samples

Gold jewellery laser welding machine jewelry soldering machine

Wuhan LS photoelectric technology co., LTD. located in Wuhan optical valley in China, is one specialized engaged in laser automation equipment system and device research and development, production, sales and service, to provide clients with laser technology solutions high-tech enterprises as a whole. The company has more than 20 years of industry experience of world first-class optoelectronic technology research and development and marketing team, dedicated to the world's highest level laser device development and laser automation equipment production and sales.

LS photoelectric 's main products are CNC plane optical Fiber Laser Cutting machine ,3 D Laser Cutting Machine, high power CNC Laser Welding Machine; all kinds of Laser Marking Machine,Medium and high power CNC laser remanufacturing equipment. All kinds of devices, such as CO2, fiber laser etc.

LS has established the perfect market service system. here to the "customer first" and "market-oriented" , experienced engineers will make it all becomes smooth and easy.

"The customer is supre me" is the premise of product quality reliable, stable and advanced technology. To overcome the technical barriers, procurement and time. the best solution is not set in stone. We have professional application knowledge, can be modified according to the comprehensive product portfolio standard products or open full custom solutions.

| After sales service | 24 hours technical support by Email or Calling. # Hardware: 1 years on all parts and labor. # Software: Whole life on update for free. # Maintenance and technological support: Whole life. |

| Quality control | # Strict control machine assembly each link, ensure the machine clean and beautiful. # 48 hours continuous working before the machine leaving factory, ensure the high quality of each machine. |

| Warranty | # 1 years guarantee of the whole machine (excluding Artificial damage) # we have sincere raw material suppliers, all of our raw material are original, not copy. # Every machine must be tested before delivery for 8 hours, all of them are absolutely qualified. # Main parts(excluding the consumables) shall be changed free of charge if there is any problem during the warranty period. |

Q: How to Install the machine

A: After receive our machine, customers do not need to install it and can use it directly.

Q: How to operate the machine? is training necessary?

A: The machine is mainly controlled by software. It's very easy, not complicated. Before shipment, we will make a simple operation manual with pictures and provide user manual of software. Generally speaking, an operator, who is not familiar with fiber laser marking machine before can still operate it very well. According to customers' requests, we can send our technician to customer' plant for machine training or customers can come to our plant for machine training if needed.

Q: What's package?

A: We have 3 layers package. For the outside, we adopt plywood case. In the middle, the machine is covered by foam, to protect the machine from shaking. For the inside layer, the machine is covered by waterproof plastic bag.

Q: What's delivery time?

A: Generally speaking, lead time is 5-7 working days after receive the payment.

Q: Can we add a protection cover?

A: Yes, we can add a protection cover if you need. We can customize the design as customers' requests.

Product Advantages:

1.Ceramic converging cavity is imported from the Britain. It is corrosion resistant and high temperature resistant ,and has 8-10 years service life.

2.High production efficiency and high welder speed, realizing automatic mass production on the production line

3.The laser head can be adjusted for 360 degree

4.The size of the light spots can be adjusted

5.The work bench can be moved in two dimensions

Application:

Suitable for welder of kettle, vacuum cup, stainless steel bowl, sensor, tungsten wire, high power diode(triode),aluminum alloy, laptop sheel, mobile phone battery, door handle, mould, electric apparatus fittings, filter, nozzle, stainless steel products, golf head, zinc alloy and so on.

artworks weld point straight line, circle, square or any plane graphs drawn by AUTOCAD.

Datas:

Model No | LS-WM200 | LS-WM300 | LS-WM400 | ||

Max. laser power | 200W | 300W | 400W | ||

Laser wave-length | 1064nm | ||||

Solder joint range | 0.1-3.0mm | ||||

Solder joint size | 0.2-3.0mm | ||||

Pulse width | ≤20ms | ||||

Pulse frequency | ≤50Hz | ||||

Mono pulse Max power | 100J/150J/200J | ||||

Type of Laser | Nd:YAG | ||||

Sighting positioning precision | RED light,CCD monitor system(optional) | ||||

Work bench stroke | 200×200mm - 1200×1200mm(optional) | ||||

Positioning accuracy | 0.02mm | ||||

RepeatablePositioning accuracy | ±0.01mm | ||||

Loading ability | ≤200KG | ||||

Power supply | 380V/3-phase/50Hz/40A | 380V/ 3-phase/50Hz/60A | 380V/ 3-phase/50Hz/60A | ||

Power system | 9KW | 12KW | 14 KW | ||

Cooling way | Water cooling | ||||

Samples

Gold jewellery laser welding machine jewelry soldering machine

Wuhan LS photoelectric technology co., LTD. located in Wuhan optical valley in China, is one specialized engaged in laser automation equipment system and device research and development, production, sales and service, to provide clients with laser technology solutions high-tech enterprises as a whole. The company has more than 20 years of industry experience of world first-class optoelectronic technology research and development and marketing team, dedicated to the world's highest level laser device development and laser automation equipment production and sales.

LS photoelectric 's main products are CNC plane optical Fiber Laser Cutting machine ,3 D Laser Cutting Machine, high power CNC Laser Welding Machine; all kinds of Laser Marking Machine,Medium and high power CNC laser remanufacturing equipment. All kinds of devices, such as CO2, fiber laser etc.

LS has established the perfect market service system. here to the "customer first" and "market-oriented" , experienced engineers will make it all becomes smooth and easy.

"The customer is supre me" is the premise of product quality reliable, stable and advanced technology. To overcome the technical barriers, procurement and time. the best solution is not set in stone. We have professional application knowledge, can be modified according to the comprehensive product portfolio standard products or open full custom solutions.

| After sales service | 24 hours technical support by Email or Calling. # Hardware: 1 years on all parts and labor. # Software: Whole life on update for free. # Maintenance and technological support: Whole life. |

| Quality control | # Strict control machine assembly each link, ensure the machine clean and beautiful. # 48 hours continuous working before the machine leaving factory, ensure the high quality of each machine. |

| Warranty | # 1 years guarantee of the whole machine (excluding Artificial damage) # we have sincere raw material suppliers, all of our raw material are original, not copy. # Every machine must be tested before delivery for 8 hours, all of them are absolutely qualified. # Main parts(excluding the consumables) shall be changed free of charge if there is any problem during the warranty period. |

Q: How to Install the machine

A: After receive our machine, customers do not need to install it and can use it directly.

Q: How to operate the machine? is training necessary?

A: The machine is mainly controlled by software. It's very easy, not complicated. Before shipment, we will make a simple operation manual with pictures and provide user manual of software. Generally speaking, an operator, who is not familiar with fiber laser marking machine before can still operate it very well. According to customers' requests, we can send our technician to customer' plant for machine training or customers can come to our plant for machine training if needed.

Q: What's package?

A: We have 3 layers package. For the outside, we adopt plywood case. In the middle, the machine is covered by foam, to protect the machine from shaking. For the inside layer, the machine is covered by waterproof plastic bag.

Q: What's delivery time?

A: Generally speaking, lead time is 5-7 working days after receive the payment.

Q: Can we add a protection cover?

A: Yes, we can add a protection cover if you need. We can customize the design as customers' requests.